500 series

This is stationary equipment. Parts are brought to the unit for processing.

Ideal for processing off-aircraft components including:

• Ailerons

• Doors

• Flaps

• Radomes

• Rudders

Compatibility:

• Metal parts

• Some plastics

Designed for maintenance-repair-overhaul (MRO) facilities:

• Separate de-coating and control room in hangar facility

• Fully automated processing

• Repair and overhaul

• Inspection

• End of life recycling

Operator station:

• Programming via touch screen

• Teach-in or data import

• Manual or semi-automated

Joystick:

• Direct axes-control

• Easy semi-automatic programming

• Single pieces, small batch sizes

Removes coatings including:

• Top coats, primer

• Mil-spec coatings

• Powder coatings

• Radar-absorbing material (RAM) coatings

• Sealants

• Conductive coatings

Operator station features:

• User-friendly human-machine interface

• Networking capability with remote monitoring

• Alarm and data capture

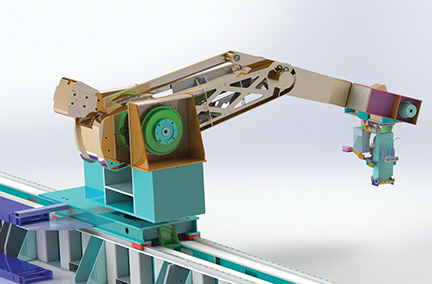

Major components:

• Laser

• Laser chiller

• Beam auto-align

• Optics

• Extraction system

• Optional contour-following module

• Optional surface inspection module