“A commitment to a greener world is the driving force behind Besnovo’s innovation."

Besnovo's Technology

Green Process

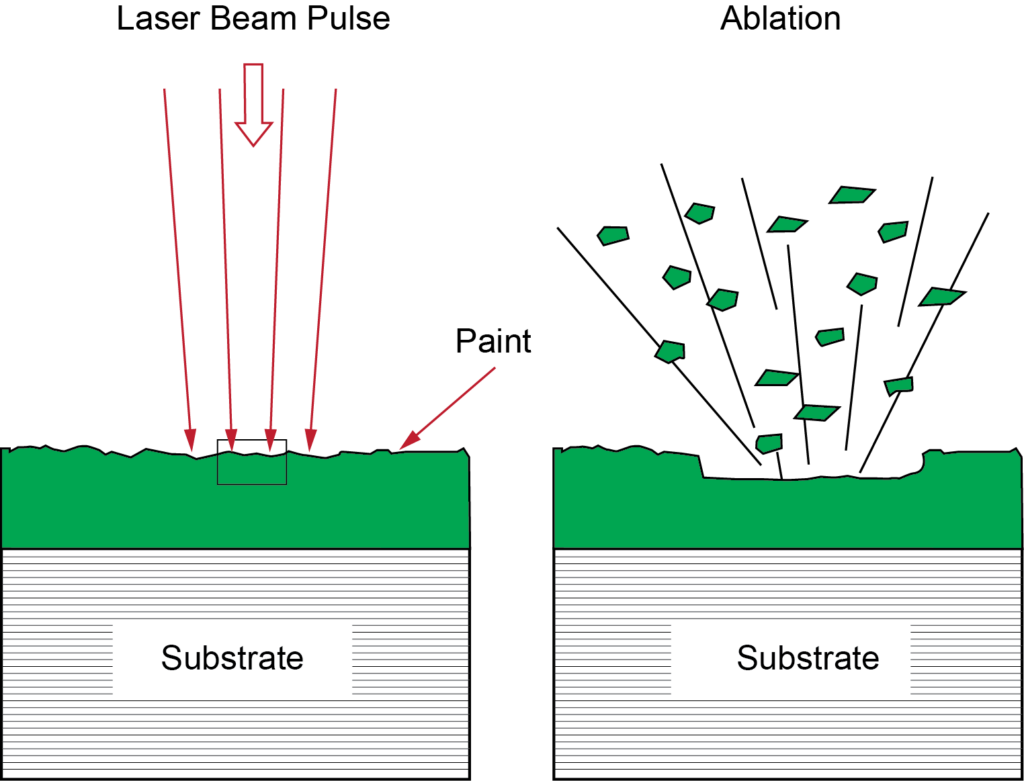

Besnovo’s laser de-coating technology eliminates the use of harsh materials for chemical stripping, media-blasting, rinsing, sanding or scraping, and the disposal of resulting hazardous wastes. Our technology generates solid waste consisting of ablated inorganic particulates, but these represent only a small fraction of the volume of coating removed. Organics are converted to gases that can be filtered and exhausted directly outside.

The significant reduction of hazardous wastes and the amount of harsh chemicals required on site can reduce, or even eliminate, the need for related permits. This reduces regulatory burdens, such as reporting, book-keeping, and site inspections.

Safety

Besnovo’s mobile units comply with international standards for safety with robots. The system is safe around people and can work simultaneously with human operators.

Adopting Besnovo’s laser de-coating process greatly reduces health and safety risks. The elimination of exposure to hazardous chemicals and residues means a human-friendly work environment.

The robotic arm uses external sensors to accurately follow the contour of object surfaces. This not only ensures the efficiency of laser ablation but also avoids collisions with the surfaces.

Besnovo’s laser de-coating process employs a closed-loop laser control system and selective de-coating technologies to ensure the safety of both metallic and composite substrates.

High-level Automation

Multiple mobile units can work simultaneously indoors or outdoors to process vehicles and increase throughput. One operator can oversee the entire process for a fully automated system. Collision avoidance is achieved via a self-guided platform.

Besnovo’s system uses an advanced SCADA system (Supervisory Control And Data Acquisition, a control system architecture). It features:

- Networking capability with remote monitoring.

- Alarm and trending capability.

- Data collection for process improvements.

CASE STUDY

The old way of chemical stripping, media blasting, sanding, waterjet, scraping:

Is labour-intensive.

Is time-consuming.

- Generates a large amount of hazardous wastes.

- Uses secondary hazardous medium.

The new way of chemical stripping, media blasting, sanding, waterjet, scraping:

Is less labour-intensive.

Requires less processing time.

- Eliminates hazardous waste.

- Does not use secondary medium.